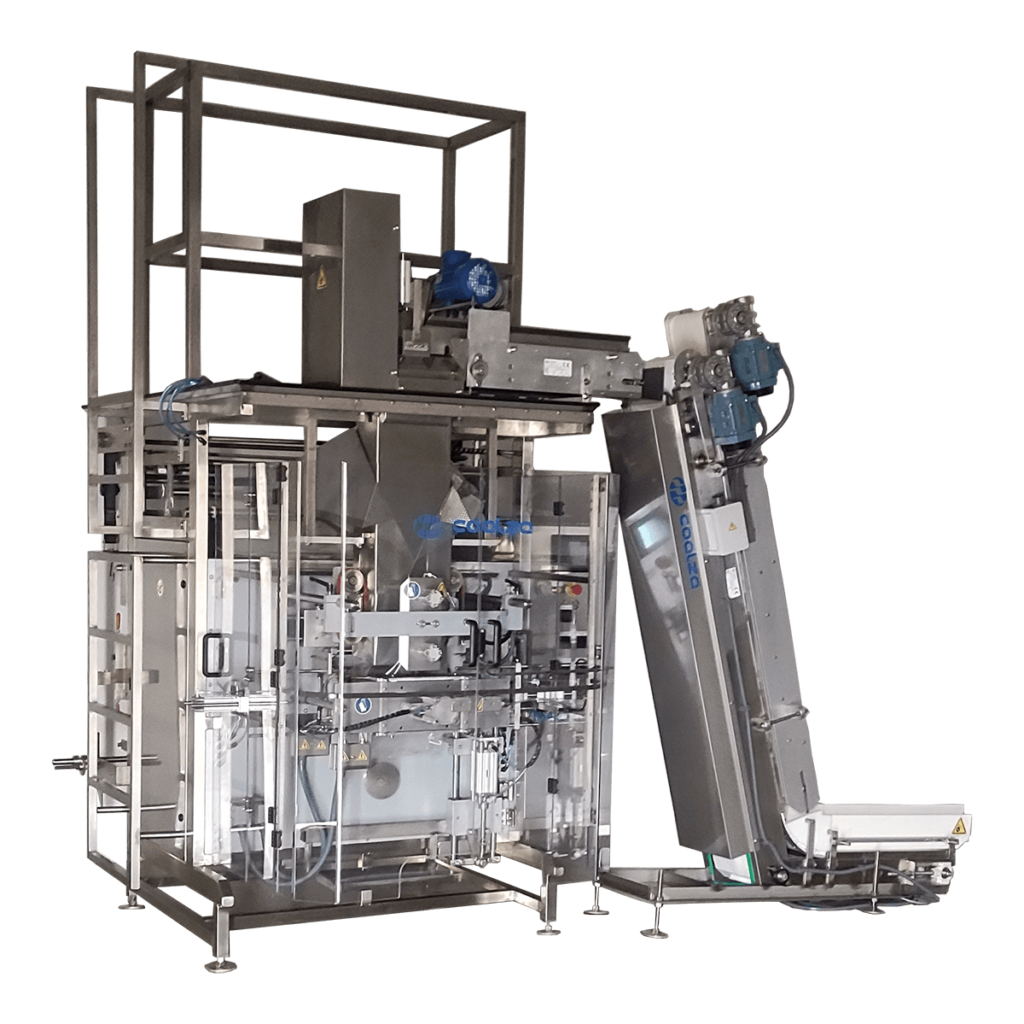

Vertical packaging machinery

If you are looking for the most advanced and efficient vertical packaging solution, Coalza offers a complete range of vertical packaging machines designed to suit every production need and product type. With over 50 years of experience in the industry, Coalza has become a benchmark in the design of vertical packaging machines that combine precision, speed and durability.

Coalza's Vertical Packaging Machines Catalogue

MAIN ADVANTAGES OF VERTICAL PACKAGING

Minimal packaging costs

Starting from film reels of different materials, the cost of the packaging is kept to a minimum compared to pre-formed packaging solutions.

Reduced production space

Its compact design allows the packaging process to be carried out in a minimum of space. In the plant, a COALZA vertical packaging machine occupies between 3 and 5 times less space than a horizontal machine for the same application.

Simplicity

COALZA has always conceived the machines to facilitate the work of the operator and maintenance manager. Its configuration and adjustment is very intuitive and can be carried out by any operator who has been trained during the start-up of the vertical packaging machine.

Rapid return on investment

The ratio of investment cost to productivity increase is optimal, allowing a return on investment in less than 12 months.

TYPES OF VERTICAL PACKAGING MACHINES

Vertical packaging machines can be classified according to several criteria.

The first classification is based on the type offilm movement.

Intermittent vertical packaging machines are those that require the film to stop in order to carry out horizontal and vertical sealing.

The process consists of:

Horizontal sealing

Coil driving

Stop

Horizontal and vertical sealing

Coil driving

Stop

Dosing (from multihead, volumetric doser, screw or other)

Horizontal sealing

In continuous vertical packagingmachines, both horizontal and vertical sealing is carried out without the need to stop the film feed, significantly improving performance in terms of bags per minute.

Vertical Packaging Machinery

How can we help you?

Coalza's Commercial Attention team responds in a personalised way to any doubts or queries that may arise through our contact form.