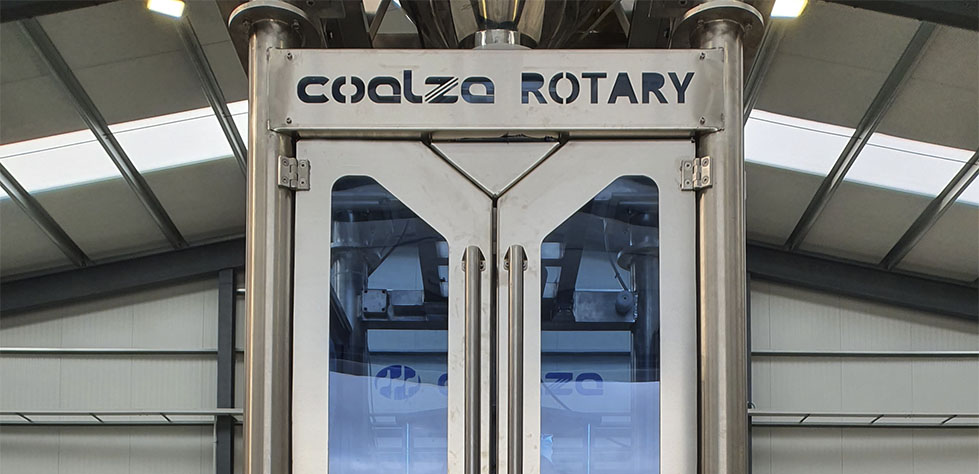

After several months working on the design and manufacture of a new model of VFFS packaging machine, Coalza is very pleased to be able to present our new SR300 rotary packaging machineto the market.

” It has taken our R+D+i team a long time, but we have finally been able to introduce to the market a high-performance VFFS packaging machine that will undoubtedly allow us to make a leap in product quality”.

The SR300 vertical rotary packaging machine is a high-performance VFFS packaging machine that will certainly meet the highest packaging requirements of any customer. At Coalza we have succeeded in obtaining a packaging machine that, thanks to the high-quality components that make it up, as well as the development carried out in the software, is able to pack at a higher speed while offering a completely airtight seal.

“Coalza SR300 rotary packaging machine, maximum performance in vertical packaging”.

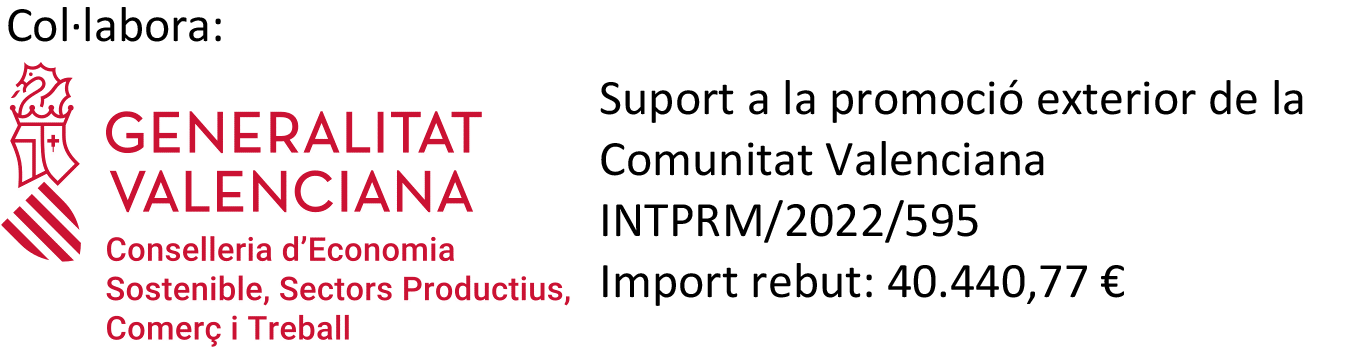

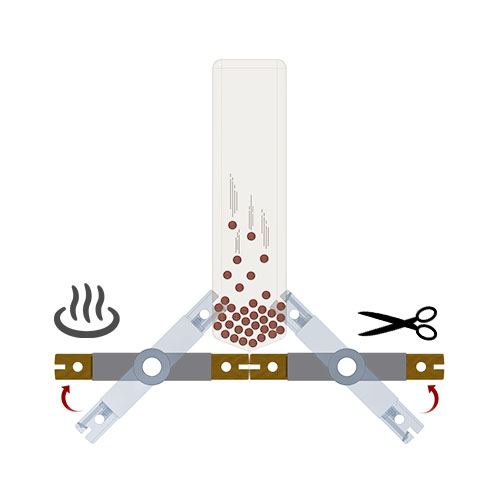

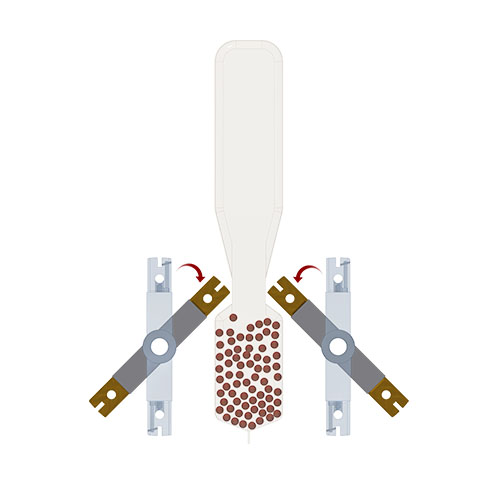

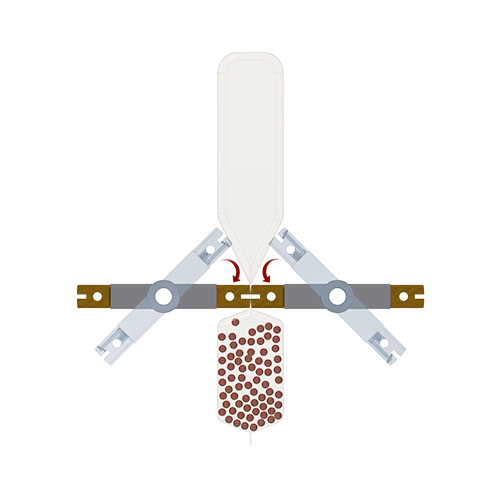

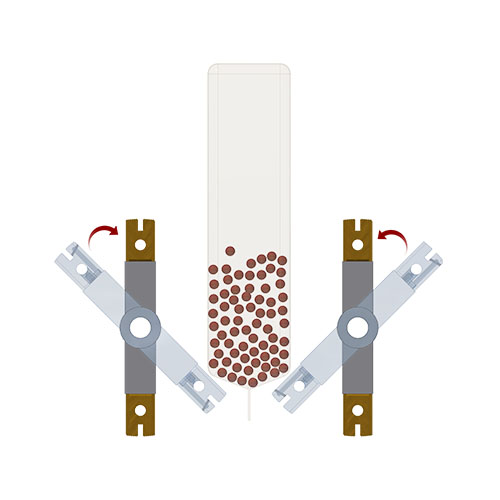

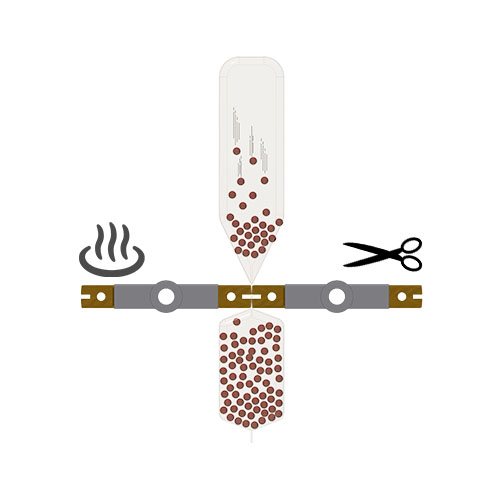

How do the jaws of Coalza’s VFFS rotary packaging machine work?

The jaws of the VFFS SR300 rotary packaging machine operate in a continuous rotary motion where the sealing and cutting of the film is carried out in a single step, allowing packaging speeds to be much higher than any other type of continuous packaging machine.

The rotary jaws provide a completely airtight and high-quality seal of the bag, as the pressure exerted by this type of jaws while sealing the film is much higher, preventing the product from being affected by the atmosphere outside the packaging. This enables the packaged product to retain its properties for a longer period.

In addition to the above mentioned features, the rotary packer is available with the stripping cutting system that allows the creation of “inflated” packages with a protective atmosphere to reduce the rate of product breakage during transport.

Which are the advantages of the VFFS SR300 rotary packaging machine?

At Coalza we have taken care of the smallest detail in the design and conception of this VFFS packaging machine, which is why we have achieved a high speed packaging machine offering the best packaging performance, but also a design made with the operator in mind, who must work with it on a daily basis for reel changes, packaging configurations, etc.

“Higher packaging speed with completely hermetic sealing and closing, because of the SR300’s rotary-continuous packaging system”.

In particular, one of the main advantages of this VFFS packaging machine is its packaging speed. Its rotary-continuous jaw movement system allows the packaging speeds of this machine to be really high, allowing maximum productivity to be achieved in any company.

Another great advantage of the VFFS SR300 packaging machine is the quick reel change system with vacuum film splicer. This means that the operator needs less time to change from one film reel to another. In addition, thanks to the ergonomic design of the packaging machine, operators will not have to perform harmful postures to carry out these reel changes, avoiding pain and muscle injuries.

Do you want more information about VFFS SR300 rotary packaging machine?

Synchronisation of all packaging machine components

The 5 servomotors incorporated in the VFFS SR300 rotary packaging machine allow the packaging process to be carried out with the minimum error rate, making this packaging machine a fully synchronised machine.

The packaging machine is equipped with servomotors in the following elements:

- Servomotor on the rear roll holder to control the film feed with maximum precision.

- Servomotor on the intermediate roller of the rewinder carriage to improve the film feed.

- Servomotor on the film feed belts, improving the accuracy of the film feed before and after sealing.

- Servomotor in vertical sealing achieving greater accuracy in the vertical sealing of the bags through control of the thermal strip.

- ervomotor in rotary jaws allows to obtain a higher speed, more precision and better sealing of the bags.

All these components reduce the need for maintenance by reducing the number of mechanical elements in the packaging machine.

Total control of the packaging process by software.

Finally, and one of the most important things that this VFSS packaging machine offers, is the software upgrade that has been carried out. This allows not only the control from the machine, but also the monitoring and integration into the plant management systems, providing detailed information and statistics about the packaging process in the plant.

¿Quieres más información sobre nuestras máquinas de envasado? Contacta con nosotros y te ayudamos en lo que necesites